The climate crisis, the global clean energy transition, and the ‘electrify everything’ global movement are driving a massive transformation of industries and infrastructure globally. Green hydrogen has the potential to create a $1 trillion business and assist reduce more than 20% of the world’s CO2 emissions. The move to green hydrogen is being pushed by governments all over the world through new rules and incentive schemes.

Green hydrogen has been seen as the top decarbonization option for steelmaking, chemical manufacturing, and in fuel cells in medium to heavy-duty land transport. In aviation and shipping, besides replacing fossil-based vehicles with hydrogen vehicles, the EU also pushes for using e-fuel made from green hydrogen and carbon captured.

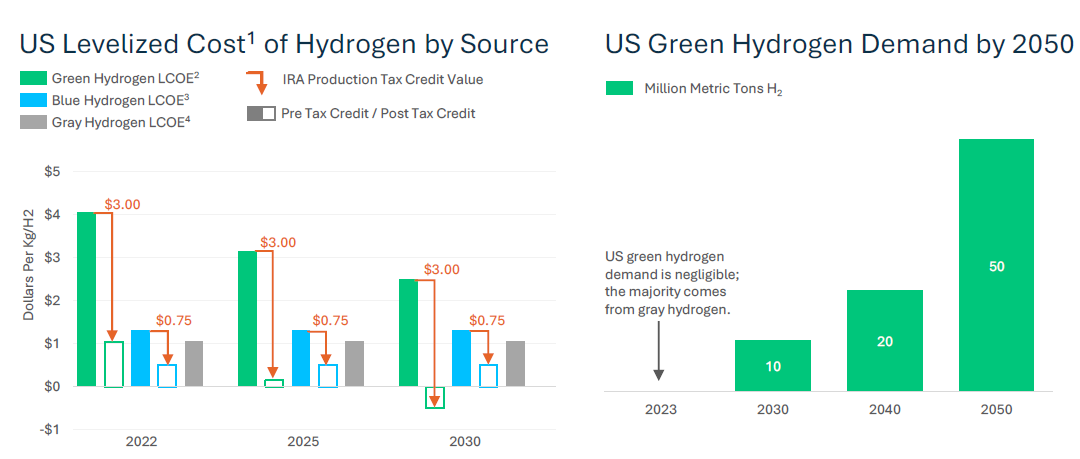

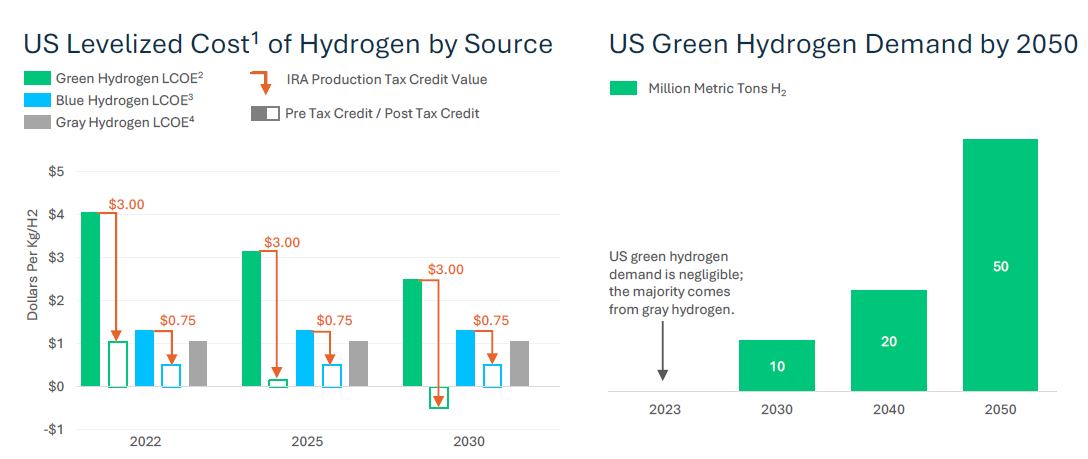

However, its high costs and the need for more infrastructure are the major hurdles. The IRA makes bold bets to unlock green hydrogen demand with production tax credits of up to $3 per kilogram. These incentives set the US up to be the cheapest source of green hydrogen in the world. For companies to qualify for the maximum tax credit, the law requires hydrogen to be produced with processes where the GHG emissions rate is less than 0.45 kg of CO2e per kg of hydrogen. For comparison, grey hydrogen produces about 24x more CO2e. Furthermore, the DOE has allocated $8B to develop six to ten regional hydrogen hubs across the US.

— From The Future of Climate Tech, June 2023, by Silicon Valley Bank

Besides subsidies, many companies are working to develop technology that can reduce the cost of clean hydrogen. especially electrolysis technologies. The two main commercial hydrogen electrolyzers currently dominating the market—Liquid Alkaline & PEM—either have low efficiency or are extremely expensive. One technology of particular interest is AEM (anion exchange membrane) electrolysis technology. AEM technology is an innovation focus area because of heap CapEx and lower OpEx with higher efficiency, and its potential to integrate directly with intermittent renewable electricity while using low-cost abundant materials.

Electrolyzer companies that have reached commercialization and are manufacturing 100s of MWs of electrolyzers are typically worth over $1B (Plug Power, Nel, Nucera). Pre-commercial electrolyzer companies with a certified, 1MW+ system design have received valuations of $200M+ (Ohmium, Electric Hydrogen, Enapter, H-Tec). Of course, there are a lot more upstart challengers working on similar technologies. No need to chase startups with hyped valuations.

We are seeing more emerging startups addressing challenges in the green hydrogen economy or building new innovations. Some examples:

- New membrane-free hydrogen production technology reduces CapEx by half compared to traditional electrolyzers with higher energy efficiency.

- Hydrogen purification is needed for all kinds of hydrogen generation methods, better performance and the same or lower cost is pursued.

- Hydrogen dispensing/fueling infrastructure is the biggest gap to support vehicles with hydrogen fuel cells. Companies offer on-site or off-site hydrogen generation, compression, and dispensing appliance uses water and electricity to produce high-purity fuel cell-grade hydrogen, powered by renewable power. There are different solutions serving the trucking industry or consumers.

- The efficient storage of hydrogen onboard trucks, ships, and planes remains one of the key challenges. Startups take the challenges of the existing hydrogen storage solutions to improve volumetric density, weight, safety, and cost. Also, a startup enables hydrogen to be stored within an organic liquid which can be handled and transported no differently than gasoline.

- Producing green hydrogen and biochar from agricultural waste streams, and monetizing the carbon credits the activity generates. More than 30% of U.S. total methane and 70% of nitrous oxide emissions come from the decomposition of agricultural wastes (from DOE), this process solves it at the same time while producing green hydrogen.

- Producing carbon neutral high purity hydrogen from recycled feedstocks such as plastics and tires.

- Using microbes to make hydrogen from oil, the team backed by Occidental Petroleum claimed they can produce hydrogen at $1 per kilogram by injecting oil-eating microorganisms inside depleted crude reservoirs.

- A hydrogen marketplace makes it easy to trade and procure hydrogen.

- A capital-light approach to hydrogen logistics by transporting green hydrogen in modular capsules over the existing freight network from green production sites to airports around the world, plus conversion kits to retrofit the existing fleet with a hydrogen fuel cell powertrain.

- Repurposing old fossil fuel reservoirs as sources of clean hydrogen, harnessing biological processes to convert leftover hydrocarbons from subsurface wells into usable hydrogen while capturing and storing CO2(use other microbes to lock it underground). This is called Gold Hydrogen.

Join us for more discoveries and discussions on investment opportunities and risks in the green hydrogen economy.